Automotive's Hidden Software Crisis: 2024 Recall Trends Uncovered

Over 13 million vehicles were recalled in 2024 from software related issues, a 35% surge from the prior year. What gives? How do we fix it?

Prefer audio? Listen here:

Today’s vehicles are rolling computers data centers, packed with millions of lines of code controlling everything from braking to entertainment. But as vehicles get smarter, they also become more vulnerable to software defects—and that’s exactly what’s driving the surge in software-related recalls.

The push toward software-defined vehicles (SDVs) and hyper-connected ecosystems has unlocked incredible innovations, but it’s also introduced a new layer of complexity. And with complexity comes problems—lots of them. The latest recall data from the full 2024 calendar year in the US paints a clear picture: software failures are a growing headache for automakers, leading to safety concerns, compliance nightmares, and skyrocketing recall costs.

About the Data

The recall data in this article is based on data from the National Highway Traffic Safety Administration (NHTSA), who enforces vehicle safety recalls in the U.S. However, NHTSA data does not distinguish between software and mechanical-related recalls, nor does it specify which electronic control units (ECUs) are affected. To bridge this gap, we used Recallsdata.com, which applies natural language processing to identify recalls that explicitly mention software or involve software-controlled electronic components. It then categorizes these recalls by ECU type.

While this analysis focuses on the U.S. market—since no global authority tracks recalls with the same rigor as NHTSA—it's likely that software-related recall numbers would be significantly higher when factoring in other regions.

Disclaimer:

Data in this article is based on publicly available recall reports and third-party analysis. While we have taken steps to ensure accuracy, the information may not reflect the full scope of all recalls from 2024. Recall classifications, affected vehicle counts, and trends are subject to change as new data becomes available or is updated. We encourage readers to consult official sources, such as the National Highway Traffic Safety Administration (NHTSA) or manufacturer recall databases, for the most up-to-date and comprehensive information.

The State of Software Recalls: 2024 Trends

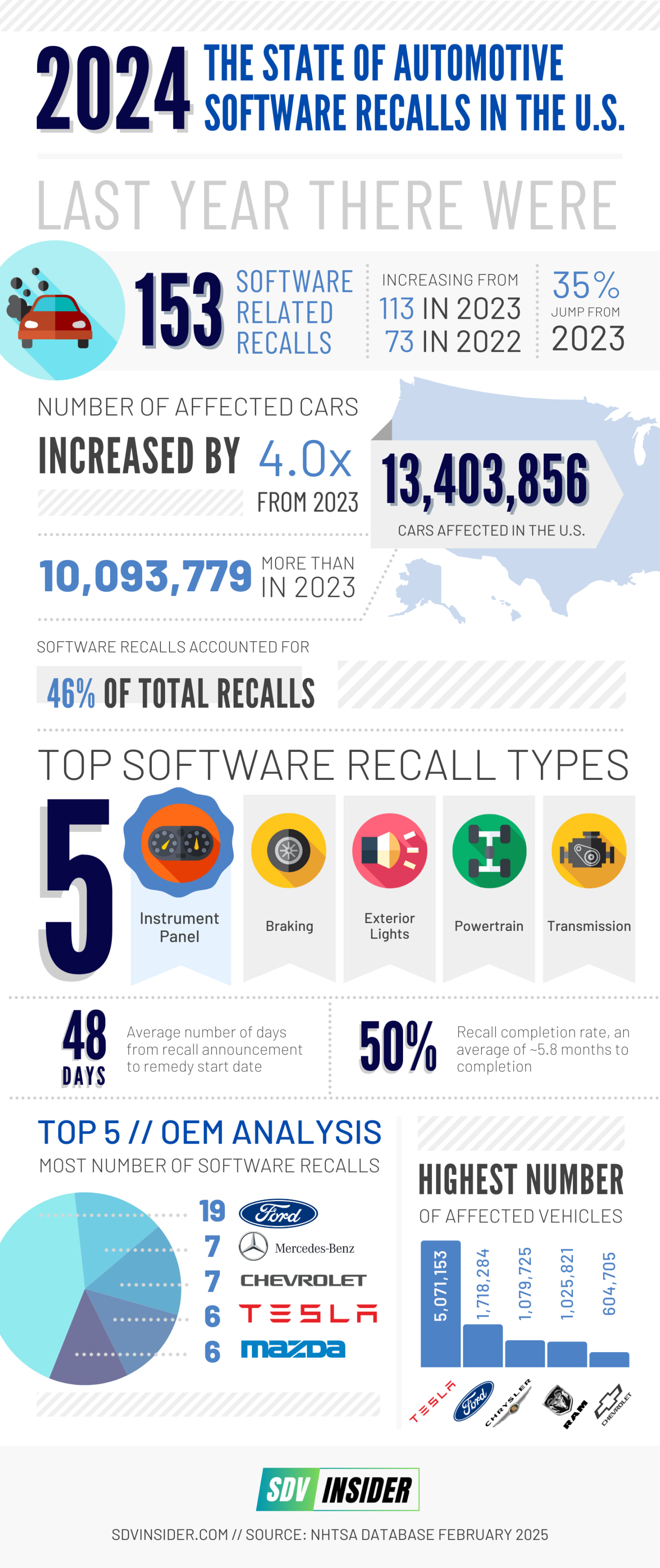

Let’s break down the numbers—software-related recalls are surging:

Total Recalls: Up 7%, rising from 795 in 2023 to 854 recalls in 2024.

Software-Related Recalls: Up 35%, rising from 113 in 2023 to 153 in 2024.

Vehicles Affected by Software Recalls: 13.4 million in 2024—a 4X increase from 3.3 million in 2023.

Share of Recalls Due to Software: Of 28.9 million total recalled vehicles in 2024, 46% were due to software issues, up from 14.2% in 2023—a 26% increase in just one year.

To recap, over 13 million vehicles recalled were impacted by software defects in just one year. When software controls everything from acceleration to airbags, even a tiny glitch can turn into a major safety risk. This surge in recalls indicates there’s a hidden software crisis in the auto industry and makes one thing crystal clear: automakers need to double down on software validation, real-time diagnostics, and proactive software update management if they want to stay ahead of the curve.

OEMs with the Most Software Recalls

Some automakers felt the sting of software issues more than others. Based on 2024 recall data, Ford led the pack with the most software-related recalls, followed by Mercedes-Benz and Chevrolet. Tesla and Mazda weren’t far behind, proving that both legacy brands and newer EV manufacturers are struggling with the same digital growing pains. Tesla’s presence is notable because while it led in total vehicles recalled (due to a few very large OTA software fixes), its number of distinct recall campaigns was slightly lower than Ford or GM’s brands.

What’s the takeaway? As cars become more connected and automated, software quality control and cybersecurity measures are no longer optional—they’re essential. The industry is learning this the hard way, and those who don’t adapt quickly could find themselves in an endless cycle of patches, recalls, and reputational damage.

Most Impacted Vehicle Components

Analyzing the content of 2024’s software-related recall campaigns reveals that certain vehicle systems were frequent trouble spots:

Instrument Panels/Clusters: 1,987,721 affected vehicles (Example: Ford had a recall on 2024 Mustangs for dark instrument clusters, remedied by a cluster software update).

Braking System: 1,984,831 affected vehicles (Example: GM recalled nearly 450,000 trucks/SUVs because a brake fluid warning light failed to illuminate due to a software bug).

Exterior Lights: 1,030,379 affected vehicles (Kia had a recall on the new EV9 to fix taillights that failed to illuminate, and Hyundai recalled thousands of 2024 Sonatas for brake lights that didn’t stay on long enough when braking).

Powertrain: 973,769 affected vehicles

Transmission: 934,598 affected vehicles

While some 2024 recalls, such as those involving electronically controlled latch components and radio ECUs, affected a large number of vehicles, they were isolated to fewer recall campaigns across different brand models. The high volume (and variability across brands) of braking, powertrain, and other safety control-related failures, underscores the need for stronger software validation, enhanced cybersecurity, and improved regulatory compliance.

Fixing Recalls: Delays & Industry Bottlenecks

One of the biggest challenges in software recalls is long resolution times, which increase risks for both OEMs and consumers. In reviewing general recall resolution timelines from NHTSA (involving software or other issues), we found that:

On average it takes ~48 days from when a recall announcement is made to a remedy start date.

On average it takes ~180 days to achieve a recall remedy completion rate of 50% of affected population

There is no central database that tracks what remedies are offered with an over-the-air fix. But we do know is that the majority of these software related recalls—with the exception of Tesla—were not fixed over-the-air, and required a visit to the dealership as prescribed in the official recall notice. While Tesla has set the bar for remedying all their software related defects remotely, the rest of the industry—while improving—has still not caught up. These lengthy recall resolution periods indicate inefficiencies in software update deployment and regulatory compliance. Delayed remedies not only increase risks for drivers but also expose OEMs to regulatory scrutiny and potential penalties.

OEMs Need to Get Ahead of Software Recalls—Before They Happen

Let’s be real: reacting to software failures after they hit the road isn’t just expensive—it’s a brand killer. With vehicles relying more than ever on complex software, automakers can’t afford to wait until something breaks to fix it. The key? A proactive, software-first recall strategy. Here’s how OEMs can stay ahead of the game:

1. Continuous Software Monitoring & Predictive Diagnostics

Use AI-powered analytics to catch software issues before they turn into full-blown failures.

Leverage real-time vehicle diagnostics to pinpoint weak spots in software architecture before they cause safety risks.

2. Expand Over-The-Air (OTA) Update Capabilities

Enabling full vehicle remote software fixes that can reach all embedded controllers and components (including safety critical).

Full vehicle OTA updates slash recall costs, improve completion rates, and keep vehicles on the road instead of stuck in the service bay.

3. Strengthen Software Testing & Validation Before Release

Adopt rigorous simulation & testing frameworks to identify flaws before they reach consumers.

Use digital twin technology at the embedded software level to replicate real-world interoperability conditions and prevent failures before deployment.

4. Improve Recall Response & Compliance Strategies

Enable instant recall notifications, via the vehicle instrument cluster or a connected mobile app. The majority of recall notices still go out by snail mail.

Automate compliance reporting to sidestep costly penalties (which can range from $20K to $200M).

Looking Ahead: The Future of Software Recall Management

With cars now defined more by code than combustion, a wait-and-fix approach is no longer sustainable. The future belongs to automakers who invest in predictive, preventive, and automated solutions to ensure software reliability. By adopting a proactive recall management strategy, OEMs can:

✅ Reduce recall-related costs

✅ Enhance vehicle safety & reliability

✅ Ensure regulatory compliance

✅ Strengthen customer trust & brand reputation

The automakers that embrace real-time diagnostics, advanced software testing, and seamless OTA updates will lead the industry. In a world where safety, compliance, and consumer confidence are everything, the winners will be the ones who prevent problems before they ever hit the road. 🚀

Today’s Article is Brought to you by Sibros

Sibros provides a complete Software-Defined Vehicle (SDV) management solution built for OEMs that leverages AI-powered data logging to debug and monitor automotive products and perform software debugging and updates live in the field. You can learn more about their Deep Connected Platform here.